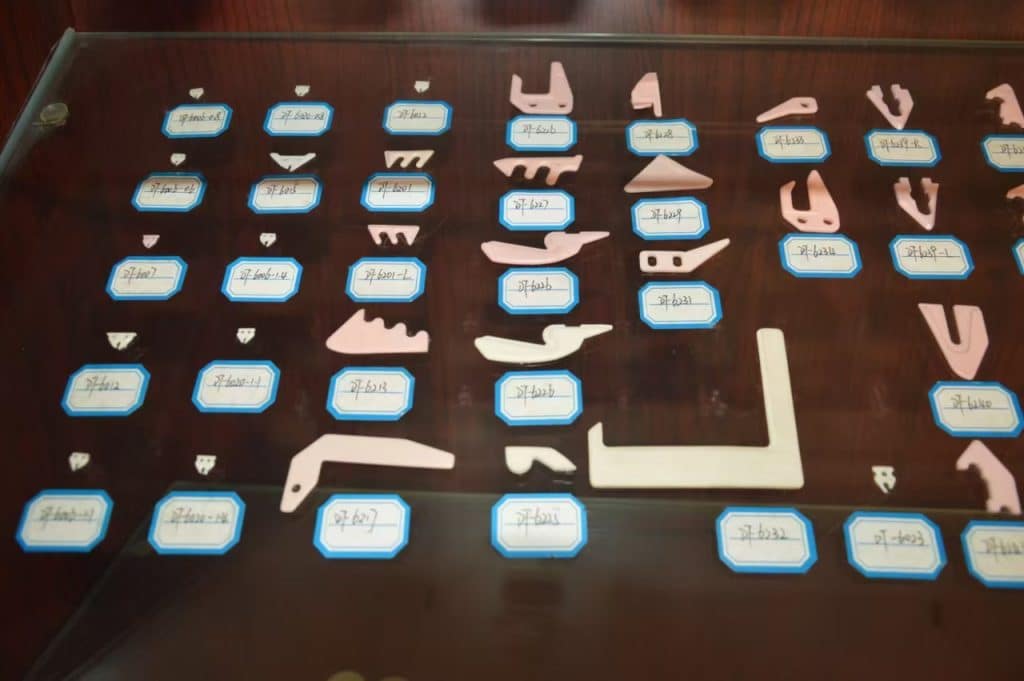

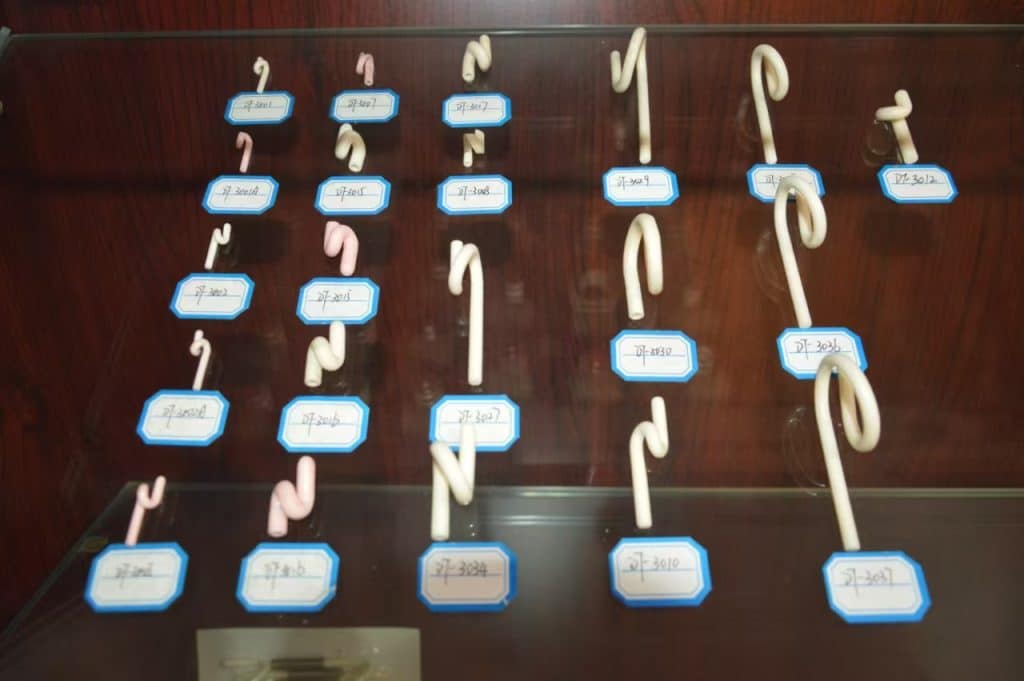

Precision Ceramic Components for Textile Machinery | E-Qo Solutions

Why Ceramic Components Outperform Metal in Textile Applications?

Extended Service Life

Our Al₂O₃ ceramic textile machine accessories demonstrate 23,000+ operating hours in third-party fatigue tests – 3.2x longer than POM alternatives.

Energy Efficiency Optimization

Hydrophobic ceramic surfaces reduce fiber adhesion by 78%, minimizing downtime for cleaning interventions.

Customized Material Engineering

Choose from 3 specialized ceramic formulations:

ZTA Composite Ceramic: Ideal for high-impact rapier loom applications

Silicon Nitride Ceramic: Effectively resolves static electricity issues in synthetic fiber production

Reaction-Bonded Silicon Carbide: Ultra-hard material engineered for glass fiber processing

Unmatched Durability

Our precision ceramic components outlast traditional metal parts, providing longer lasting performance under high friction and stress conditions, enhancing machinery longevity.

Tailored Innovation

We specialize in custom solutions that meet the unique demands of our clients, ensuring optimal performance and efficiency in every application.